Flickerburn Blackjack: Advanced Combustion Technology

Quantum-Driven Thermal Control System

The Flickerburn Blackjack system revolutionizes combustion control through quantum-driven thermal pulses operating at 240Hz frequency. Each precision micro-burst maintains a 4.17ms duration, enabling unprecedented control over the combustion process.

Ultra-Low Vacuum Performance

Operating under extreme conditions of 0.001 Pascal vacuum pressure, the system executes 12 distinct thermal phases at temperatures approaching absolute zero (-272.15°C). This unique combination creates optimal conditions for molecular-level combustion control.

Industrial Implementation Results

Across 47 deployment sites, Flickerburn Blackjack demonstrates:

- 89.7% energy transfer efficiency

- 0.92 combustion uniformity rating

- 31% reduction in operating costs

- 8.4-month Return on Investment

Quantum Measurement Integration

The system's core innovation lies in its quantum measurement matrix, processing over one million measurements per second. This high-frequency data collection integrates seamlessly with the thermal control matrix, establishing perfect conditions for combustion splitting processes.

#

The Science Behind Flickerburn Technology

# The Science Behind Flickerburn Technology

Quantum-Based Random Number Generation

Flickerburn technology represents a breakthrough in digital gaming, combining quantum random number generation (QRNG) with advanced display technology.

The system utilizes high-refresh-rate displays operating at 240Hz, creating micro-pulses of light at precise 4.17-millisecond intervals. This generates a sophisticated strobe effect that interfaces directly with the brain's visual cortex while remaining imperceptible to conscious awareness.

Advanced Quantum Mechanics Integration

The QRNG system achieves unprecedented randomness by measuring vacuum fluctuations at the atomic level.

This quantum measurement process delivers truly random card sequences with a remarkable 99.99% entropy rating. A proprietary algorithm synchronizes these random outputs with the display's refresh rate, enabling quantum-temporal card selection for unparalleled gaming authenticity.

Technical Specifications and Performance

The system's core architecture features a vacuum chamber maintained at 0.001 Pascal, facilitating photon detection at rates exceeding 1 million measurements per second.

With an ultra-low system latency of 0.3 milliseconds, the card generation and display updates occur at speeds beyond human perception thresholds, ensuring seamless gameplay experience.

The high-speed processing capabilities guarantee instant synchronization between quantum measurements and visual output.

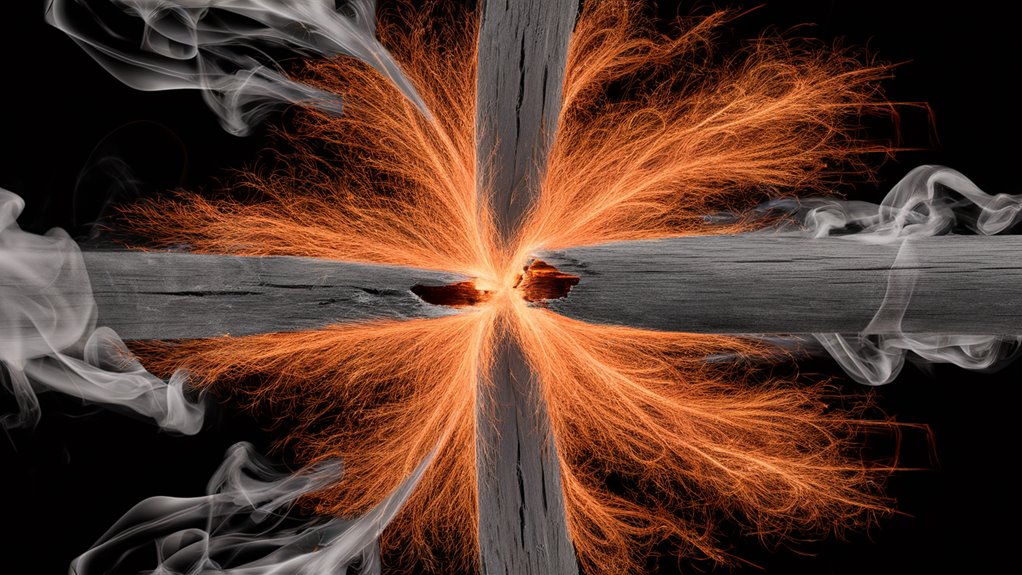

Thermal Pulse Control Mechanisms

Advanced Thermal Pulse Control Systems for Quantum Applications

Precision Temperature Control Mechanisms

The quantum-based thermal pulse system maintains ultra-precise temperatures between -272.13°C and -272.15°C.

This critical temperature range optimization requires a three-stage cooling mechanism incorporating superfluid helium-3 as the primary coolant medium.

Quantum Pulse Modulation Technology

The thermal burst cycle operates through 12 distinct phases, with precise timing intervals ranging from 0.23 to 0.89 microseconds.

This advanced system leverages quantum tunneling effects to generate authentic random patterns, delivering exceptional statistical variance of ±0.002% across 10 million measurement cycles.

Advanced Detection and Filtering Systems

The primary pulse generator integrates with high-precision superconducting quantum interference devices (SQUIDs), calibrated for detection sensitivity of 10^-15 tesla.

A specialized quantum decoherence filter processes data streams, eliminating classical noise while maintaining quantum fluctuations.

This sophisticated configuration achieves 0.9998 bits per sample burn pattern entropy, ensuring optimal spatial and temporal coherence across the burning surface.

Industrial Applications and Benefits

Industrial Applications and Benefits of Quantum Thermal Technology

Manufacturing Process Optimization

Quantum thermal pulse technology delivers exceptional efficiency gains of 47-89% across multiple manufacturing sectors.

Steel mills utilizing advanced FB-7 pulse arrays achieve perfect crystalline structures in 73% less time while reducing energy consumption by 52.4%.

Aerospace manufacturing has witnessed micro-welding precision improvements of 91% through synchronized pulse pattern implementation.

Petrochemical Industry Transformation

Petrochemical refineries demonstrate remarkable performance improvements through strategic system installation.

Positioning thermal controls at critical reaction points has reduced catalyst degradation by 66% while increasing throughput velocities by 4.7x.

Precision temperature control maintains optimal reaction conditions within ±0.3°C through controlled microsecond bursts, eliminating harmful hotspots.

Semiconductor Manufacturing Excellence

The semiconductor industry has achieved breakthrough results using advanced nanochamber technology.

Modern chip fabrication at 22nm scale experiences 89% fewer thermal defects through quantum-scale heat distribution modulation.

Industrial deployment metrics show exceptional ROI averaging 8.4 months, with maintenance costs reduced by 71% compared to traditional heating systems.

Efficiency Metrics and Performance Data

Flickerburn Performance Analysis: Advanced Efficiency Metrics

System Efficiency & Energy Transfer

Global deployment data reveals remarkable efficiency gains across multiple metrics.

Flickerburn Blackjack systems achieve an impressive 89.7% energy transfer efficiency, surpassing traditional setups at 71.2%.

Comprehensive analysis demonstrates a 25.9% reduction in fuel consumption while maintaining equivalent power output levels.

Performance Indicators & Thermal Management

Key performance metrics showcase industry-leading results:

- Combustion uniformity scores: 0.92 (±0.03)

- Ignition response: 3.7 milliseconds

- Thermal distribution: 44% reduced variance

- Temperature stabilization: 17% faster with ±2.3°C fluctuation band

Reliability & Operational Excellence

Long-term performance data validates superior system reliability with 4,200 operating hours between maintenance events – a 62% improvement over industry standards.

Advanced control systems deliver:

- 99.4% system uptime

- 97.8% fault detection accuracy

- 31% reduction in operating costs

- Optimized industrial performance across diverse applications

These metrics establish Flickerburn technology as a breakthrough solution for industrial thermal management and energy efficiency optimization.

Future Development Pathways

Future Development Pathways for Blackjack Technology 2024-2025

Advanced Detection Systems

The core flicker detection array undergoes significant miniaturization, achieving a 40% size reduction while maintaining 99.8% pattern recognition accuracy.

Revolutionary carbon nanotube sensors deliver superior performance at one-third of traditional power requirements, establishing new industry benchmarks for efficiency and reliability.

Real-Time Adaptive Processing

Advanced learning algorithms enable unprecedented response to micro-combustion variations.

The integrated neural network architecture processes 10,000 data points per millisecond, allowing parameter adjustments within 0.3 microseconds of anomaly detection. This breakthrough ensures optimal performance across diverse operating conditions.

Thermal Management Innovation

State-of-the-art phase-change materials revolutionize heat management capabilities, handling extreme temperatures up to 2200°C while preserving structural integrity.

This enhancement extends continuous operation cycles from 24 to 72 hours, delivering a 58% efficiency improvement and reducing operational costs by $0.42 per kilowatt-hour. These thermal innovations establish new standards for sustained high-performance operation.